Disposable ECG electrode machines are important for making medical tools. These machines help create electrodes used to check heart health. They cut, shape, and add special materials to make sure the electrodes work well.

More people need disposable ECG electrodes because healthcare is improving. For example:

- The worldwide ECG market was worth $5.2 billion in 2020 and grows 5.1% yearly.

- Disposable ECG electrodes may grow from $1.2 billion in 2023 to $2.1 billion by 2032.

- Home health devices are growing fast at 9.5% yearly, increasing the need for disposable tools.

These machines help meet growing needs while keeping products safe and useful.

Key Takeaways

- Disposable ECG electrodes help check heart health. They are used once to stop infections and keep things clean.

- New machines make production faster and better. These machines cut, add glue, and put gel on electrodes automatically for better quality.

- Checking quality is very important when making electrodes. Machines look for mistakes and make sure each electrode is safe to use.

- Buying better machines saves money over time. They use fewer materials and need less work, helping healthcare needs grow.

- Picking good machines and helpful support is important. This keeps production running well and makes sure quality stays high.

Overview of Disposable ECG Electrodes

What are disposable ECG electrodes?

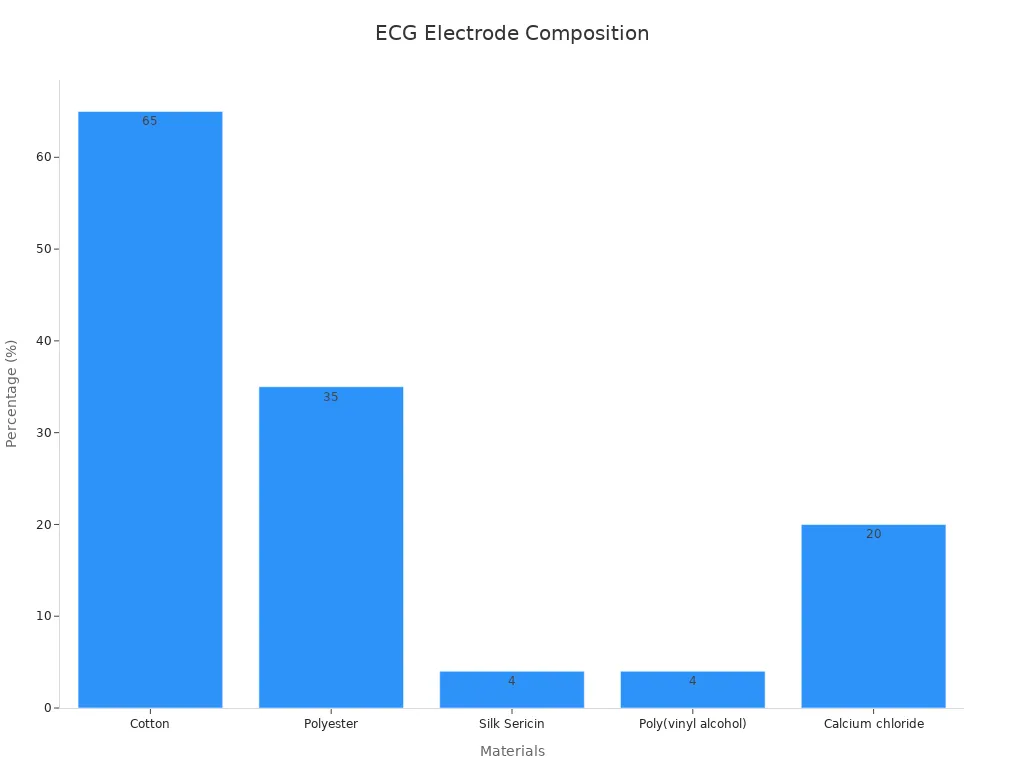

Disposable ECG electrodes are one-time-use tools for checking heart activity. They have layers that work together to send heart signals to a machine. The top layer is often made of cotton (65%) and polyester (35%) for strength and comfort. Inside, materials like silk sericin (4%), poly(vinyl alcohol) (4%), and calcium chloride (20%) improve stickiness and signal flow.

These materials help send clear signals and avoid skin problems. New ideas like MEDTEX P-130 and printed electronics make them light and good for wearable devices. This is important because modern healthcare needs both comfort and accuracy.

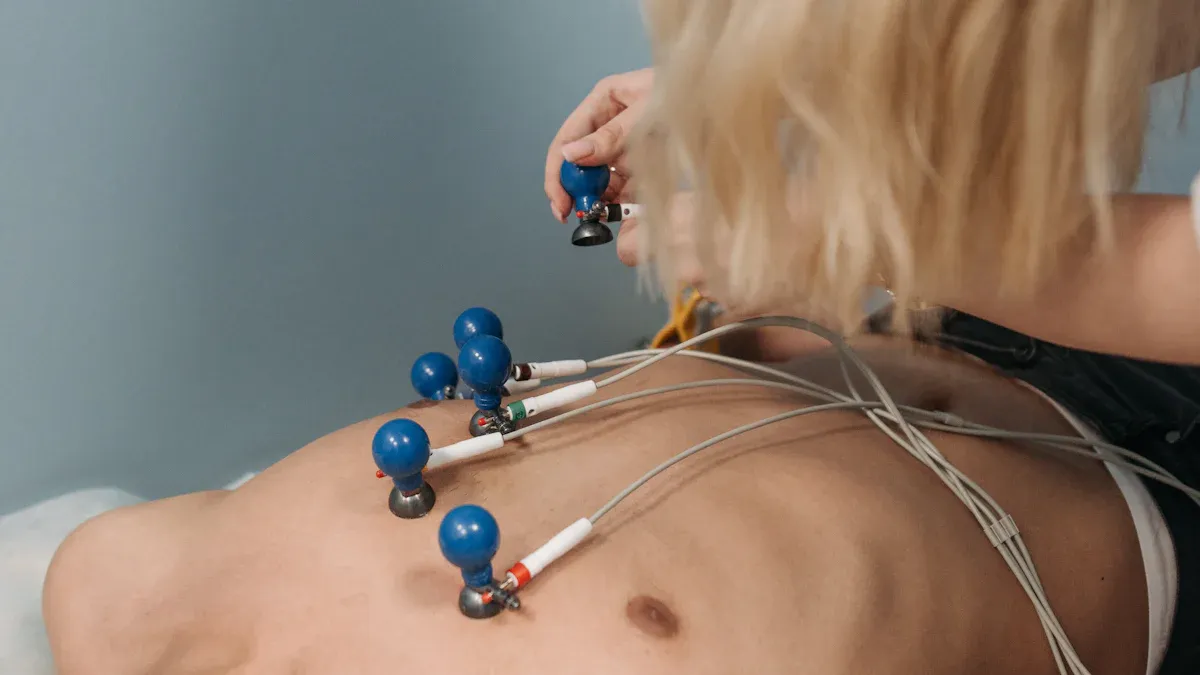

How are they used in heart health?

Disposable ECG electrodes are key for checking heart health. They are used in hospitals, clinics, and even at home. These tools find irregular heartbeats, check heart rates, and track heart health. Since they are single-use, they lower the chance of spreading germs, which is great for clean environments.

Better technology has made them more useful. Electrochemical tech makes signals clearer, and printed electronics help them fit into wearable devices. These updates make them great for long-term heart checks, especially for people with heart problems. In North America, many people use them for better care. In Asia Pacific, their use is growing fast due to more healthcare spending.

Disposable ECG electrodes are very important for safe and accurate heart checks, whether in hospitals or wearable devices.

Key Components of Disposable ECG Electrode Production Equipment

Cutting and shaping machinery

Machines for cutting and shaping are key to making ECG electrodes. They cut each electrode to the right size and shape. This is important because small mistakes can affect how well they work. Modern machines use advanced methods like lasers or die-cutting. These techniques are very accurate and save materials from being wasted.

Fast cutting machines help make more electrodes quickly. Smooth operation means they can handle lots of materials without slowing down. This is needed to meet the rising demand for ECG electrodes. Many machines also have automatic features. Automation reduces human errors and makes products more consistent.

Adhesive application systems

Adhesive systems are also very important. They spread a thin, even layer of adhesive on the electrode. This adhesive helps the electrode stick to the skin securely. It must be strong enough to stay in place but gentle to avoid skin problems.

Modern adhesive systems use precise tools to apply the adhesive. This ensures every electrode gets the same amount. Consistency keeps the product quality high. Some systems also control temperature. This helps the adhesive work well in different conditions.

The adhesive and how it’s applied can affect performance. For example:

- Bad adhesive can make the electrode fall off too soon.

- Uneven adhesive can cause discomfort or wrong readings.

Conductive gel dispensing units

Conductive gel is very important for ECG electrodes. It helps send signals from the skin to the machine. Gel dispensing units make sure the right amount of gel is added to each electrode.

These units often use automatic systems for accuracy. Automation ensures every electrode gets the same gel amount. Some units check the gel’s thickness to keep it effective during long production runs.

Good gel application improves the electrode’s performance. Even gel helps capture clear signals. This is crucial in medical care, where accuracy matters for patients.

Did you know? Making ECG electrodes depends on good machines and materials. Even air quality can affect how well production goes.

Quality control and testing systems

Quality control systems are key to making reliable ECG electrodes. They check if each electrode meets strict medical rules. Advanced tools help ensure the electrodes work well and give accurate results.

How do quality control systems work?

These systems check many parts of production. They look at size, shape, adhesive, and gel on each electrode. Sensors and cameras find problems like uneven adhesive or wrong gel spots. Fixing these issues early stops bad products from being sold.

Testing also checks how well electrodes send signals. This ensures they give clear readings during heart checks. For example, tests may mimic real-life conditions like heat or humidity to see how electrodes perform.

What standards do these systems follow?

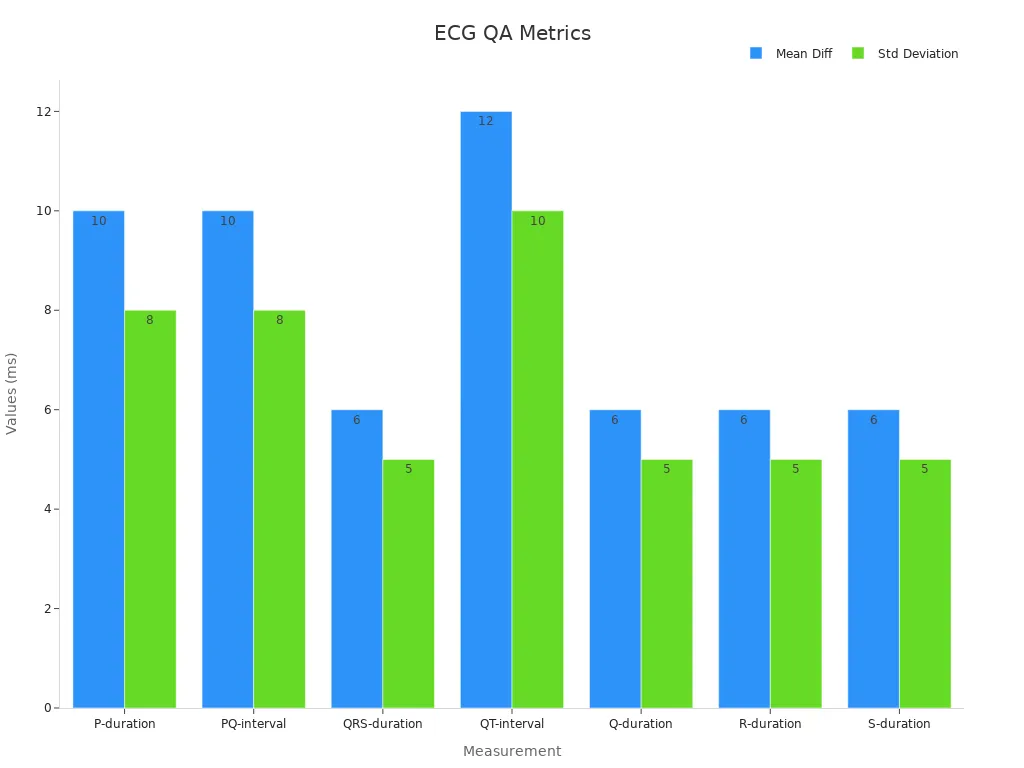

Quality control follows strict rules to keep high standards. For ECG electrodes, limits for measurement errors are set. The table below shows some of these rules:

| Measurement | Allowed mean difference (ms) | Allowed standard deviation (ms) |

|---|

| P-duration | ± 10 | 8 |

| PQ-interval | ± 10 | 8 |

| QRS-duration | ± 6 | 5 |

| QT-interval | ± 12 | 10 |

| Q-duration | ± 6 | 5 |

| R-duration | ± 6 | 5 |

| S-duration | ± 6 | 5 |

These rules make sure electrodes are precise for heart monitoring. If errors go beyond these limits, the product may not work well.

Why is testing important?

Testing ensures every ECG electrode works properly. It keeps products consistent in large batches. Automated systems can test thousands of electrodes per hour. This speed helps meet the growing demand for disposable ECG electrodes.

The chart below shows the allowed mean differences and standard deviations for ECG measurements. It highlights the accuracy needed in production:

Benefits of advanced quality control systems

Modern quality control systems have many advantages. They find defects early, making electrodes more reliable. Automation speeds up testing and improves efficiency. These systems also help meet safety rules, ensuring products are safe to use.

Tip: Take care of quality control tools to keep them working well.

By using strong quality control systems, you can make high-quality ECG electrodes. These electrodes will meet the needs of doctors and patients.

How the Production Process for Disposable ECG Electrodes Works

Material preparation and cutting

The process starts by getting the right materials. Polyester and cotton blends are chosen for their strength and comfort. These materials are cleaned and checked to meet medical standards. This ensures they are safe for use on skin.

Next, machines cut the materials into the needed shapes. Tools like lasers or die-cutters make precise cuts. This keeps all pieces the same size and shape. Accurate cutting reduces waste and ensures a good fit for the final product.

Tip: Check cutting machines often to keep them working well.

Adhesive and gel application

After cutting, adhesive and gel are added. Adhesive systems spread a thin, even layer on the electrode. This helps it stick to the skin without causing irritation. The adhesive must stay sticky even with sweat or movement.

Then, conductive gel is applied. This gel helps send signals from the skin to the machine. Automated systems add the right amount of gel to each electrode. Even gel application is important for clear signals and accurate readings.

Did you know? Poor gel application can cause bad signal quality and wrong results.

Assembly and lamination

After adhesive and gel are added, the layers are put together. Machines stack the layers in the correct order. This step needs to be very precise to make sure the electrode works well.

Next is lamination. This step bonds the layers into one strong piece. Heat and pressure are used to seal the layers without harming them. Laminated electrodes stay together even in tough conditions.

Finally, the electrodes are checked for defects. Faulty ones are removed to keep quality high. The good electrodes are then packed and sent out for use.

Note: Good assembly and lamination are key for making safe and reliable electrodes.

Quality inspection and packaging

Quality checks and packaging are the last steps in making disposable ECG electrodes. These steps make sure the electrodes are safe and meet medical rules.

How does quality inspection work?

Quality checks look for problems in each electrode. Machines with cameras and sensors find issues like uneven glue or gel. They also test if the electrodes send signals correctly.

Automated systems make this process faster. They can check thousands of electrodes every hour. Some machines test how electrodes work in different conditions, like heat or humidity.

Tip: Keep inspection machines adjusted to ensure they stay accurate.

Packaging process

Packaging keeps electrodes clean and safe during storage and shipping.

Here’s how packaging is done:

- Sterilization: Electrodes are cleaned to remove germs before being packed.

- Sealing: Machines put electrodes in pouches or trays and seal them. This keeps out air and moisture.

- Labeling: Each package gets a label with details like batch number and instructions.

- Final check: Workers or machines check the packages for damage or mistakes.

The packaging materials must be strong and safe for medical use. Many companies use special plastic or foil to keep electrodes sterile.

Why are these steps important?

Quality checks and packaging make sure disposable ECG electrodes are safe to use. Bad electrodes can give wrong results or harm patients. Good packaging keeps them clean and ready for use in hospitals or homes.

By doing these steps well, manufacturers can provide reliable products for doctors and patients.

Benefits of Using Advanced Disposable ECG Electrode Production Equipment

Faster production process

Modern machines make disposable ECG electrodes faster. Automated systems do tasks like cutting and adding adhesive quickly. This reduces the need for workers and increases how many electrodes are made. You can meet more demand without lowering quality.

These machines also waste less material. Precise tools cut materials carefully, saving money and helping the environment. By improving how production works, you can make more electrodes while keeping them high-quality.

Tip: Take care of machines regularly to avoid breakdowns and keep them running smoothly.

Better accuracy and uniformity

Accuracy and uniformity are very important for ECG electrodes. Advanced machines make sure every electrode meets strict medical rules. They apply adhesive and gel evenly, avoiding problems like bad signals or discomfort.

The table below shows how advanced machines improve quality:

| Complexity Level | Average PCC | Average RMSE (mV) | Average SNR |

|---|

| Easy | 0.977 | 0.041 | 16.682 |

| Medium | 0.970 | 0.047 | 15.785 |

| Hard | 0.817 | 0.098 | 11.101 |

These numbers show how advanced tools make signals clearer and more reliable. They ensure electrodes work well in different situations. You can trust these machines to give consistent results, even in busy hospitals.

Easier large-scale production

Modern machines are great for making lots of electrodes. As demand grows, these systems can handle more work without losing quality.

Studies show that scalable machines help businesses grow. High-quality products and new technology attract more customers. With healthcare spending increasing, there are more chances to expand. Advanced machines let you produce more while keeping costs low and quality high.

By using scalable tools, you can stay ahead in the market. These machines help balance costs and quality, ensuring success in the long run.

Long-term cost-effectiveness

Buying advanced machines for making disposable ECG electrodes saves money over time. The upfront cost might seem high, but the savings later are worth it. These machines are built to use less material, work faster, and cut costs. They help you make more electrodes with fewer resources, saving money in the long run.

A big benefit is wasting less material. Modern cutting and adhesive tools are very accurate. They reduce mistakes and save raw materials. This lowers costs and helps the environment. Automated systems also need fewer workers, which reduces labor costs.

The growing need for disposable ECG electrodes shows why investing in better machines is smart. The table below shows how the market is growing:

| Year | Market Size (USD) | CAGR (%) |

|---|

| 2024 | 1.2 Billion | N/A |

| 2033 | 2.5 Billion | 8.9 |

This growth means more people need high-quality medical tools. With efficient machines, you can meet this demand and keep costs low.

Another advantage is that modern machines last longer. They need fewer repairs and less maintenance, saving money. Taking care of them regularly keeps them working well and makes them last even longer.

Tip: Keep up with regular maintenance to make your machines last longer and get the most out of your investment.

By using advanced equipment, your business can succeed for years. You’ll save money, meet growing demand, and keep your products high-quality, staying ahead in the medical device market.

Factors to Think About When Picking Disposable ECG Electrode Machines

Cost and Budget

Cost is important when choosing production machines. Look at both upfront costs and long-term expenses. Disposable ECG electrodes cost more per piece but are easier to use. They also help stop infections, making them popular in healthcare. Reusable electrodes save money over time and are better for the environment.

More people need disposable ECG pads for better patient care. These pads are comfy and give accurate results. They are great for home and mobile health checks. Buying advanced machines helps meet this demand while keeping costs low.

Machine Quality and Reliability

Good machines make sure electrodes are made well and work right. Pick equipment that follows strict medical rules. Important things to check include heart rate accuracy, RR interval timing, and signal clarity. The table below shows key benchmarks:

| What to Check | What It Means |

|---|

| Heart Rate | Counts heartbeats per minute using R peaks. |

| RR Interval | Measures time between R peaks in the ECG signal. |

| QRS Amplitude | Finds the difference between the highest R peak and lowest Q or S peak. |

| Signal-to-Noise Ratio (SNR) | Shows how clear the signal is. |

| Skin-Electrode Contact Impedance | Tests electrode performance; should be under 5 MΩ for all ages. |

| Coefficient of Variation (CV) | Checks how much QRS wave data changes from the average. |

Reliable machines reduce mistakes and make sure electrodes meet medical standards.

Customizing Machines for Special Designs

Customizing lets you adjust machines for different electrode designs. Advanced tools help place electrodes better, improving signals and saving time. The table below compares design efficiency:

| Design Type | EDA Difference | ECG Signal Clarity | EMG Difference |

|---|

| Quality Optimized | 2.5% | High | 0.8% |

| Area Optimized | 4.5% | Moderate | 1.3% |

Modern design tools make production faster and easier. Customizable machines help you stay competitive in the medical device industry.

After-sales support and maintenance

Taking care of your disposable ECG electrode production equipment is very important. Good support helps your machines work well for a long time. Here’s why it matters and what to look for:

Why is after-sales support important?

When you buy machines, you need help if problems happen. Machines can break or stop working right, slowing down production. Strong support fixes issues fast and keeps things running smoothly.

Tip: Pick suppliers with 24/7 help. Quick fixes save time and avoid delays.

Key features of good after-sales support

- Expert Help: Choose companies that offer skilled help for fixing problems. They should provide remote help and visit your site if needed.

- Easy-to-Get Parts: Make sure spare parts are available quickly. Waiting for parts can stop production.

- Staff Training: Some suppliers teach your team how to fix small problems. This helps them understand the machines better.

- Warranty Plans: Check how long the warranty lasts. Longer warranties save money on repairs.

Maintenance services to consider

Regular care keeps machines working their best. Preventing problems saves money and makes machines last longer. Focus on these services:

| Maintenance Type | Purpose | Frequency |

|---|

| Cleaning and Lubrication | Stops parts from wearing out | Weekly or Monthly |

| Calibration | Keeps production accurate | Every three months |

| Software Updates | Makes machines run better | When needed |

| Full System Inspection | Finds hidden problems | Once a year |

Note: Write down maintenance dates to spot repeated problems.

Long-term benefits of strong support

Good support and care save money over time. Well-kept machines use less energy and lower costs. Reliable help also makes it easier to handle surprises.

By focusing on after-sales services, your machines will stay dependable and efficient for years.

Machines for making disposable ECG electrodes are very important. They help create tools that check heart health and work well. Newer machines make production faster and more accurate. This helps meet the rising need for healthcare products. Using advanced machines also saves money over time and keeps quality steady.

When picking machines, think about how reliable they are. Look for tools you can customize and companies that offer good support after buying. Smart choices lead to better results for your business and the people who use your products.

FAQ

What are disposable ECG electrodes made of?

Disposable ECG electrodes are made from polyester, cotton, and gel. These materials make them comfortable, strong, and good at sending signals. Skin-friendly adhesives are used to avoid skin irritation.

Why are disposable ECG electrodes single-use?

Single-use electrodes help stop infections and keep things clean. They are more hygienic for medical use. Reusing them could harm signal quality and patient safety.

How does production equipment improve electrode quality?

Modern machines cut, apply adhesive, and add gel accurately. This makes the electrodes consistent and precise. Automation also lowers mistakes, making them safer for medical care.

Can production machines handle custom designs?

Yes, many machines can be adjusted for special designs. You can change settings to make electrodes in different shapes or sizes. This helps meet specific medical needs.

How do you maintain production equipment?

Take care of machines by cleaning, oiling, and checking them often. Follow the maker’s instructions for updates and inspections. Good maintenance keeps machines working well for a long time.